info@lmpchemicals.com

info@lmpchemicals.com

+91 9825321249

+91 9825321249

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

info@lmpchemicals.com

info@lmpchemicals.com

+91 9825321249

+91 9825321249

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

LMP Chemicals as a Group Company of Arti Enterprise. Also as Manufacturer & Traders (Arteck Products) of Specialized Chemicals for SS surface finish treatments.

Our company LMP CHEMICALS, located in G.I.D.C., Ankleshwar, Gujarat, India is a leading organization in surface treatment related to Metal Finishing / Electroplating since 1994.

Our product S-2 is specially developed by us for Stainless Steel surface treatment in compliance with ASTM A380. Plant is fully equipped with some of the most modern facilities for Quality Control Systems to adhere the process of chemical treatment.

We have highly skilled, qualified & experienced team for marketing & production. With the help of rich experience & the unique guide lines of our company M.D. Mr. Surendra Rai, Group LMP has succeeded in achieving the peak position within a short span of time.

By S-2 Care, Pickling & Passivation process will assure the optimum restoration of the chrome oxide passive layer.

Why pickling & Passivation necessary:

Stainless Steel Behavior:

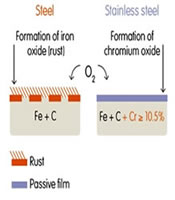

Stainless steel is essentially the group of iron alloy which exhibit significant resistance to corrosion. Stainless Steel is composed of at least 68% iron, 10.5% chromium and less than 1.2% carbon. The chromium properties provide stainless steel with superior corrosion resistance. Additional elements are: Nickel, Titanium, Copper and Molybdenum.

NOTE: The addition of Nickel makes steel “Stainless”.

Due to affinity of chromium it combines with oxygen & form Chromium-Oxide which becomes tenacious (strongly attached to the surface of SS) and self renewing. This layer is only about 130 angstroms (1A = 10-10m) thick and protects the base stainless steel from corrosion. The self renewing property of the film means that if the film gets removed or damaged (as happens when the surface is machined or scratched), the film forms again by itself! All that is required is oxygen which, as we know, is present in air ! This is what makes stainless steel special.

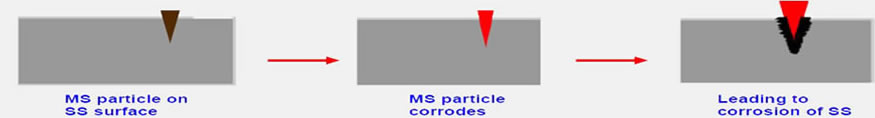

The iron particle rusts initially and chlorides from the atmosphere will then combine with the corrosion products forming ferric chloride which in turn makes stainless steel corrode.

PICKLING:

SUMMARY:

Pickling(Chemical de-scaling) of stainless steel is required to remove scale, heat tint & to create the self-repairing oxide film on surface which enables it to become more passive and corrosion resistant.

PASSIVATION:

SUMMARY:

Proper Passivation with a nitric acid-based agent will dissolve surface contamination and assist in the optimal restoration of the chrome-oxide passive layer. If Passivation is not carried out, stainless steel can rust due to surface-free iron and, since chlorides are also often absorbed from the atmosphere, some ferric chloride will be produced. Prolonged contact with ferric chloride will eventually initiate pitting and crevice corrosion on the stainless steel surface. Failure of stainless components due to corrosion can reach catastrophic proportions. The cost in time, materials, rectification, and lost production can be tremendous.

Copyright © 2020 L.M.P Chemicals