Applications:

- ACC (Air Cooled Condensers)

- Condensers

- Gas Coolers

- Heat Exchangers

- Flare Line Cleaning

- Waste Heat Recovery Units (WHRU)

- U Tube (Hairpin) Exchangers

- Fin Fans

- Evaporators

- Furnaces

- Reactors

- Heat Recovery Steam Generators

- Vertical Combined Feed Exchanger

- Turbine Blades

- Dehydrators

- Boilers

- Pipe/Pipeline

- Chillers

- Tanks and Vessels

Mechanical Jobs:

- Hydro jetting: Up to 600 bar

- Hydro Testing: Up to 500 bar

- HE Box-up

- Vessel & Column Cleaning

- Reactor Catalyst Changing

- Servicing of Valves

- Mechanical Cleaning of Storage Tanks

SERVICES THROUGH ARTI ENTERPRISE(FOR LMP CHEMICALS):

ARTI ENTERPRISE specializes in Passivation of stainless steel alloys. We can handle equipments: vessels, framework, plumbing manifolds and piping. We have the capability of passivating large containments on site utilizing our Mobile Passivation Servicing Unit. The complete process is monitor by ARTI ENTERPRISES.

STAGES OF PASSIVATION:

- INSPECTION:

We inspect every part for cleanliness prior to the Passivation process to check for hydrocarbons such as grease, oil, lubricants, forming compounds, cutting fluids, wax markings as well as metallic residue and other contaminates which would affect the Passivation process including quality of material and welds.

- PASSIVATION BATH:

The Passivation process is done through nitric acid based solutions. This process is widely accepted commercially. Most of the Passivation procedures are performed as per ASTM-A380 specifications provided to our clients with the same high level of controls.

OTHER SERVICES:

- Pickling & Passivation Job work at your facility of fabricated Stainless Steel Vessels, Tanks, Equipments, Trays & Plates etc. The process is done by Spraying or Swabbing & by dipping (with PP tanks).

- Deputation of skilled manpower with supervisors at your site.

- Picking and Passivation: Job at our premises for your equipment vessels or components.

- Mechanical Polishing: Mechanical Polishing (Grinding) & Buffing of equipments and vessels.

- Electro polishing: Through our state of art in house facility Specially for Electro polishing of “INNER” portion of pipes, tubes, other equipments.

- Degreasing plants and machineries.

- Mobile Services for customers who have systems in place.

PICKLING:

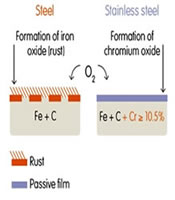

- As we know that the underground/base steel are coated with a thin film of Chromium Oxide which creates a barrier in the formation of rust and also to the moisture. But during various steel fabrication processes like heat treatment (heat tint), weld scale, Rust (discoloring oxide layer caused due to the expose of free ferrous atoms to the surrounding atmosphere).

- All these fabrication practices removes the Chromium Oxide layer from Stainless steel surface & cause the corrosion of stainless steel. To stop this contamination of ferrous ions and to increase corrosion resistance, We need to pickle the surface by the help of pickling process.

SUMMARY:

Pickling(Chemical de-scaling) of stainless steel is required to remove scale, heat tint & to create the self-repairing oxide film on surface which enables it to become more passive and corrosion resistant.

PASSIVATION:

- To remove the presence free ferrous ions, oxide-scale, rust ferrous particles, metal chips or other non-volatile deposits will promote pitting corrosion at the cells set up between the “free” iron and stainless steel. Mechanical action, embedded iron particles, or oxygen starvation can easily occur in the workshop or during fabrication. Surface-free iron particles, dust, grit, and iron-oxide contaminants arise from handling, fabrication/forming, welding, grinding, machining, paint, crayon marks, polishing, tumbling, and workshop cross contamination.

- This affects the chemical behavior of stainless steel or disturbs its surface free ions behavior. Due to which the contaminants penetrate the passive film, absorb and generate chlorides, ferric chloride, or produce inorganic chlorides by decomposition of organic compounds, such as PVC and marking materials. Passivation also aids in the rapid development of the passive surface layer on the steel.

SUMMARY:

Proper Passivation with a nitric acid-based agent will dissolve surface contamination and assist in the optimal restoration of the chrome-oxide passive layer. If Passivation is not carried out, stainless steel can rust due to surface-free iron and, since chlorides are also often absorbed from the atmosphere, some ferric chloride will be produced. Prolonged contact with ferric chloride will eventually initiate pitting and crevice corrosion on the stainless steel surface. Failure of stainless components due to corrosion can reach catastrophic proportions. The cost in time, materials, rectification, and lost production can be tremendous.

info@lmpchemicals.com

info@lmpchemicals.com

+91 9825321249

+91 9825321249

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

info@lmpchemicals.com

info@lmpchemicals.com

+91 9825321249

+91 9825321249

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India

Plot No. 4617/D, Near Megamani Cross,. GIDC, Ankleshwar, Gujarat, India